Production Flow

Our End to End Process

Welcome to Akash Granite’s Infrastructure page! Here, we take pride in showcasing our state-of-the-art facilities that enable us to produce high-quality granite products for our clients. At Akash Granite, we have invested heavily in our infrastructure to ensure that we have the necessary machinery, tools, and equipment to produce granite products that meet international quality standards.

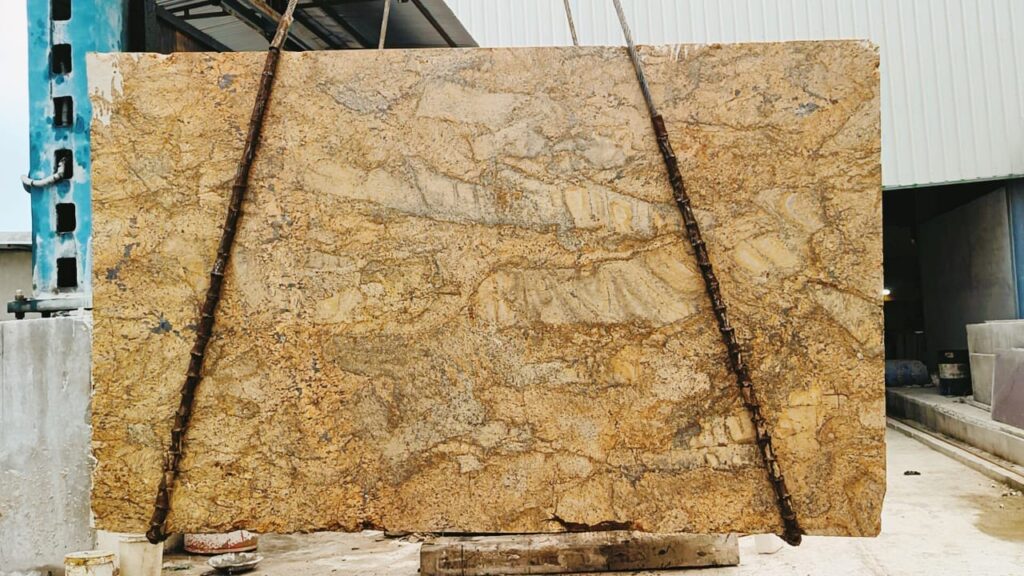

At Akash Granimarbo, we use advanced techniques to extract granite blocks from our quarry, ensuring that we minimize waste and maximize yield.

The Block Extracted by Mining through Advanced Technology Machinery and loaded through Derrick Crane on the Truck

Tranported to our Factory. Block undergoes through Vacuum Process where the Cracks got filled and Coating should be done on the Block throug High Quality Fiber

During the dressing process, the block of stone is typically cut into more manageable sizes Then, the surfaces of the stone are smoothed And then Block is Ready to move inside Our Highly Advanve Technology Multicutter Machines

To cut a granite block after dressing it, the block is first secured to a cutting table or bed using clamps or other mechanical fasteners. The cutting tool is then brought into contact with the granite block and guided along a pre-determined cutting path.

Grinding is an important step in the line polishing process, as it removes any rough or uneven spots on the surface of the stone, creating a level surface that's ready for polishing. The grinding process typically involves using a series of diamond abrasive pads with varying grits, starting with a coarse grit pad to remove any high spots or rough areas on the stone surface.

Epoxy treatment is a common way to enhance the appearance and durability of granite surfaces. When applied to a ground granite block, epoxy can help to fill any small cracks, chips, or other imperfections in the surface of the stone, creating a smoother and more even finish.

The final step of polishing on a line polisher involves the use of diamond abrasive pads with the highest grits to achieve a high level of shine and gloss on the surface of the stone.

Request a Quote

Ready to Work Together? Fill out the below form and we will get in touch shortly!

Learn More From

Frequently Asked Questions

Akash Granimarbo is a leading manufacturer and supplier of high-quality granite products for residential and commercial projects.

Akash Granimarbo offers a wide range of granite products including slabs, tiles, countertops, vanity tops, and more.

The delivery time depends on the size and complexity of your order. Akash Granimarbo will provide you with an estimated delivery time based on your specific requirements.

Akash Granimarbo accepts various payment options including credit cards, debit cards, and net banking.